Graphene as a Chemical Additive for Latex Paint

11 de December de 2024Introduction – Objectives and Context

Graphene exhibits unique electrical, mechanical, and thermal properties that can significantly improve various technical applications, including the paint and coating industry. Although graphene’s use as a corrosion inhibitor in industrial coatings is well-documented, its application in architectural and decorative coatings, especially waterborne latex resin coatings, is still limited.

Recent Lab research conducted by Gerdau Graphene has shown promising fresults in terms of viscoelastic properties and moisture resistance. . Graphene-latex films exhibited lower water vapor transmission rates, higher surface hydrophobicity, reduced porosity and modified mechanical properties to resist better against abrasion stresses. These characteristics are crucial for improving the longevity and performance of latex paints. For thoses reasons, 2 field tests were planned to confirm theses first lab observations.

Background: Graphene waterborne dispersion

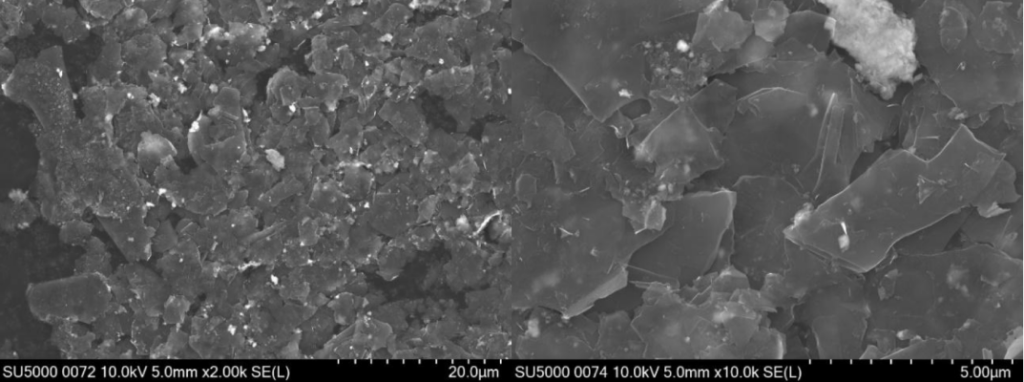

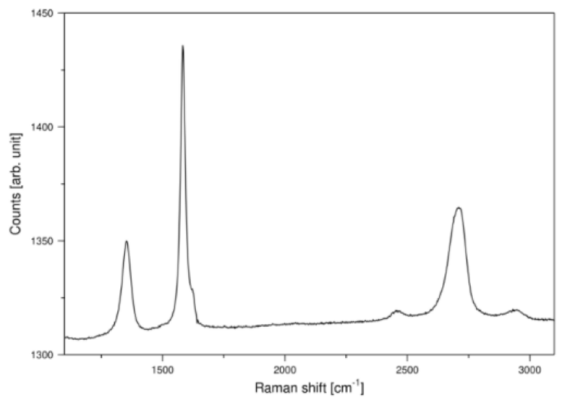

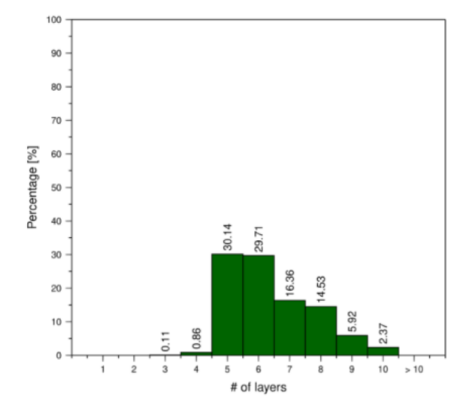

Gerdau Graphene produces waterborne graphene dispersions for compatibility with latex paints. Graphene dispersions produced by Gerdau Graphene were found to be highly stable and effective when integrated into waterborne latex paints. These dispersions typically have a high solids content (10 wt.%) and demonstrate excellent long-term stability. Characterization involved Scanning Electron Microscopy (SEM) and Raman spectroscopy to analyze crystalline defects and interlayer numbers. The SEM images showed deagglomerated graphene sheets with a lateral size around 4 µm, indicating a well-dispersed state (figure 1). Raman spectroscopy further confirmed the quality of the graphene, highlighting its low defect levels and high crystallinity (figure 2). The number of Intercoupled graphene layer number is below 10 (figure 8), this material can be considered as genuine few-layer graphene (figure 3).

Experiments

Experiment 1: Floor Latex Paint in Pindamonhangaba, Brazil (2022)

- Paint preparation: A generic commercial formulation of floor latex matt paint was used, meeting Brazilian standards. The paint was produced on a pilot scale (1000 liters), with and without 0.05 wt. % graphene. After preparation, the paints were stored at room temperature for characterization and performance tests, including pH, viscosity, stability at 60ºC, field tests, and abrasion resistance.

- Field Test: Two bike lanes were painted at Gerdau Pindamonhangaba as depicted in figure 4. In both locations, asphalt surfaces were thoroughly cleaned with a high-pressure water gun before application. It is essential to emphasize that both locations were free from any previous coating. After drying, 2 or 3 coats of latex paint were applied using a paint roller. The latex paint was initially diluted with an additional 30% of water for the application of the first coat and with only 10% for the subsequent coats. Only one coat per day was applied, allowing the paint to cure overnight. The applications conditions for each location are detailed in table 1. A monthly visual inspection was conducted to assess the wear rate of each paint application.

| Area name | Application start date | Final date | Substrate | Coat number | Graphene |

| A1 | 18/03/2022 | 27/09/2022 | Asphalt | 2 | 0.05% |

| A2 | 14/04/2022 | 27/09/2022 | Asphalt | 3 | No |

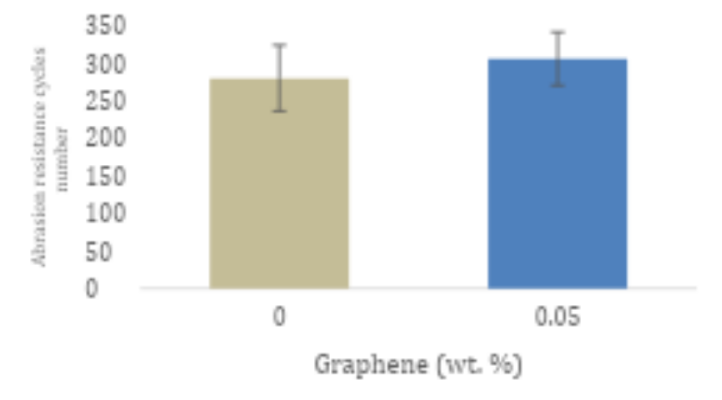

- Results: The floor latex paint produced with graphene was tested both in the lab and in the field. Lab tests showed no significant differences in abrasion resistance when compared to paint without graphene as shown in figure 5. However, field tests at the Gerdau Pindamonhangaba plant revealed that the graphene-enhanced paint exhibited better durability under real-world conditions, particularly during the rainy season. The paint with graphene maintained a more uniform coloration and exhibited less wear compared to the non-graphene paint, suggesting that graphene may help reduce paint consumption and improve durability as illustrated in figure 6.

Experiment 2: Floor Latex Paint in Mogi das Cruzes, Brazil (2023)

- Paint preparation: An industrial-scale production of 5000 liters of floor latex paint, formulated with and without 0.05 wt. % graphene. The same raw materials were used, except for necessary pigment adjustments to avoid color discrepancies.

- Field Test: In the Mogi das Cruzes field tests, the paint was applied to create bike lanes. Concrete surfaces were thoroughly cleaned with a high-pressure water gun before application. It is essential to emphasize that the location was free from any previous coating. After drying, 3 coats of latex paint were applied using a paint roller. The latex paint was initially diluted with an additional 30% of water for the application of the first coat and with only 10% for the subsequent coats. Only one coat per day was applied, allowing the paint to cure overnight. Paint with graphene and reference paint without graphene were applied alternatively every 1- to 2-meter-long interval as shown in figure 7 in order to make sure external aggressive conditions will affect in the same way the evolution of both types of paint. A monthly visual inspection was conducted to assess the wear rate of each paint application.

- Results: Different areas showed varying levels of wear, influenced by environmental conditions such as humidity and mechanical stress. In high humidity areas, both graphene and non-graphene paints showed similar wear levels, likely due to adhesion issues. In protected areas, wear was minimal for both types. However, in areas exposed to moderate stress, graphene-enhanced paint demonstrated significantly better performance, retaining its color and showing less wear over time.Differences in wear between both conditions (with/without graphene) started to be significantly noticeable after approximately 200 days exposure and it accelerated during the rainy season (September-March) as illustrated in figure 8. The positive impact of graphene in terms of durability is easily noticeable.

Experiment 3: High PVC Wall Paint with Graphene Incorporation

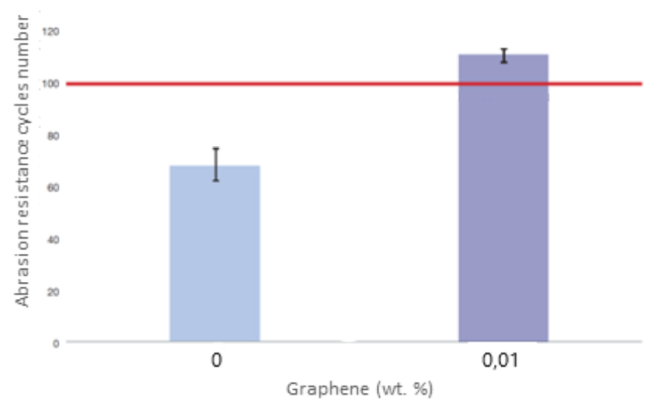

- Preparation of the paint: A standard commercial formulation of high PVC latex matte paint was provided. The paint was produced on a small scale (1 liter) with and without 0.01% graphene. Performance testing focused on abrasion resistance according to ABNT NBR 15078 (without abrasive paste.

- Results: Graphene at 0.01% improved abrasion resistance significantly), suggesting it could replace wash promoters like sodium silicate without affecting pH as shown in figure 9.

Conclusions

Graphene has shown promise as a performance-enhancing additive for latex paints, particularly in improving durability and resistance to wear (without abrasive paste). Future projects (NanoDUR generation 2) will focus on developing graphene-based additives that enhance both durability and abrasion resistance with abrasive paste involving new technologies such as covalent graphene functionalization.